API 570 Process Piping Inspection

An innovative solution designed to tackle the intricacies of intricate configurations, concealed or hard-to-reach pipelines, elevated piping systems, and more!

What is API 570 in Process Piping Inspection?

API 570 is a comprehensive standard that governs the inspection of all hydrocarbon and chemical process piping that has been put into service. This code also covers piping that has been classified as “out of service” but still poses a potential safety hazard due to ongoing deterioration

Why Do You Need Process Piping Inspection?

Timely inspections play a crucial role in thoroughly examining both the internal and external surfaces to guarantee their integrity. Our team of experts excels at identifying potential areas of degradation, which aids in devising effective repair plans. Through meticulous inspection, we minimize safety and operational risks while ensuring cost-effectiveness compared to the consequences of piping failure or the necessity for frequent replacements.

Origin Endeavours - A Hub of Cutting-Edge Solutions

We harness state-of-the-art technology and validated screening methodologies to mitigate costly craft support. In numerous instances, we have the capability to deliver inspection services without necessitating plant downtime, ensuring expeditious completion within hours rather than days. With an unparalleled spectrum of nondestructive testing and examination techniques at our disposal, you can rest assured knowing that we deliver inspection services of the utmost quality, reliability, and cost-effectiveness.

Here at Origin Endeavours, we hold our valued customers in the highest regard, and it is our fervent hope that you grant us the opportunity to serve you and experience the distinctive difference we offer.

Our API 570 – Process Piping Inspection

- Inspection, analysis and reporting of piping to API 570 requirements.

- Development of piping inspection packages targeting CUI (corrosion under insulation), CUPS (corrosion under pipe supports) or general corrosion specific to the site's external conditions and internal degradation modes.

- Ultrasonic thickness inspection and Phased Array capabilities.

- PEC (pulsed eddy current) testing

Our Process Piping Services

- Equipment maintenance strategy development

- Development of piping inspection packages

- Design and construction of process piping networks

- Greenfield and brownfield fabrication and installation

- On-site modifications/alterations

- Specialist welding and fabrication

Process Piping Inspection FAQs

What Is Process Piping Inspection?

Process piping is a pipe that transports gases, water, chemicals, and various fluids, facilitating their transformation into a final product. Whether it’s a straightforward arrangement or an extensive network of interconnected tubes, pipes, hoses, valves, gaskets, fittings, and other crucial components, process piping is susceptible to degradation due to continuous changes. To uphold safety and productivity, process piping inspection diligently monitors the condition of this system.

What Does Process Piping Inspection Include?

Delving into the realm of process piping inspection, our proficient inspectors meticulously assess both the internal and external surfaces. With keen eyes, they scrutinize every inch, meticulously identifying potential damage mechanisms and complications. Their comprehensive evaluation encompasses erosion, pitting, corrosion, fretting, and an array of other issues. Following this meticulous examination, we meticulously analyze the gathered data. This allows us to formulate precise inspection reports that adhere to the stringent requirements dictated by the appropriate inspection codes pertaining to process piping.

Who Needs Process Piping Inspection?

Process piping is a prevalent feature in various industrial settings such as chemical and petrochemical plants, pharmaceutical facilities, oil refineries, automotive plants, aircraft manufacturing facilities, water treatment plants, and more. These pipelines come into contact with water, gas, chemicals, and other elements, making them susceptible to deterioration. To ensure safety, it is crucial to inspect and maintain them regularly, following the application of FSS standards and techniques outlined by the American Petroleum Institute (API) 579.

Other Services

Pressure Vessel Inspection

Pressure vessels are containers that hold liquids or gases at a pressure that is significantly higher than ...

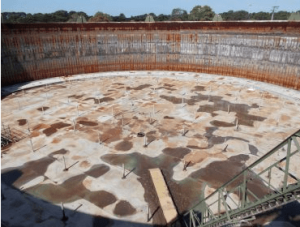

Above Ground Inspection

Above Ground Storage Tank inspections from Origin Endeavours ensure the safety and integrity ...

Expediting | Third Party Inspection

Origin Endeavours can act as an impartial inspector when you want to ensure that your order for expensive and ..

NDT Inspection

Nondestructive testing (NDT) is the process of inspecting, testing, or evaluating materials, components, or assemblies for ...